Carbon fiber has long been recognized for its exceptional strength-to-weight ratio, making it a popular choice in industries such as aerospace, automotive, and sports equipment. Its ability to provide both rigidity and lightweight performance has positioned it as a key material in high-performance applications. On the other hand, colored fiberglass offers flexibility and durability while allowing for a wide range of aesthetic finishes. When combined with carbon fiber, colored fiberglass enhances the material’s visual appeal while maintaining its strength and functionality. The growing trend of hybrid composites, such as who manufactures carbon fiber with colored fiberglass, is becoming increasingly popular due to its ability to merge the performance benefits of carbon fiber with the design possibilities of colored fiberglass. These hybrid materials are being utilized in various fields, including consumer goods, automotive parts, and even in the fashion industry, where both strength and appearance are important.

What is Carbon Fiber and Colored Fiberglass? – Who Manufactures Carbon Fiber with Colored Fiberglass?

Carbon Fiber Basics

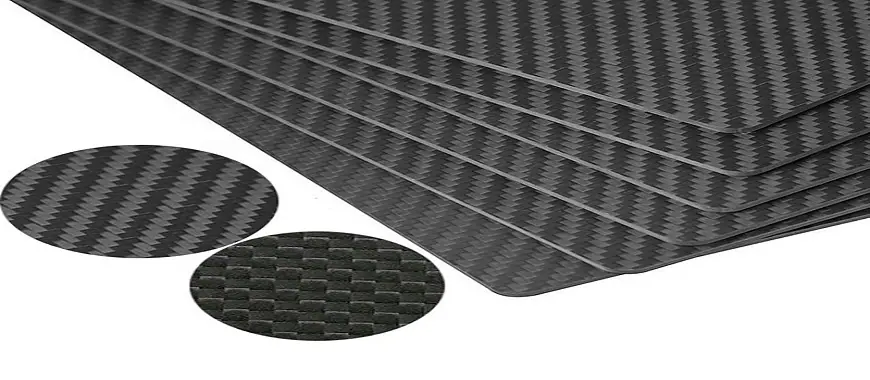

Carbon fiber is a high-performance material known for its remarkable strength and low weight. It is made by heating organic polymers, typically polyacrylonitrile (PAN), to high temperatures in an inert environment, transforming the material into thin fibers. These fibers are then woven into sheets and often combined with resin to create a solid composite material. Carbon fiber is widely used in industries such as aerospace, automotive, and sports equipment due to its exceptional strength-to-weight ratio. It is stronger than steel but much lighter, making it ideal for applications where reducing weight without compromising strength is crucial.

The primary advantages of carbon fiber include its durability, high tensile strength, and resistance to corrosion. These properties make it particularly useful in environments that demand high performance, such as in aircraft structures, high-speed vehicles, and bicycles. Carbon fiber also has excellent thermal conductivity and can withstand extreme temperatures, making it versatile for a wide range of demanding applications.

Colored Fiberglass

Colored fiberglass is a variation of traditional fiberglass that incorporates pigments during the production process, allowing manufacturers to create vibrant colors while maintaining the material’s structural integrity. Regular fiberglass is made from molten glass that is drawn into thin fibers and then woven or formed into sheets. The addition of color is typically achieved by adding glass fibers pre-coated with colored resins or by mixing pigments directly into the resin.

Unlike the traditional transparent or neutral appearance of regular fiberglass, colored fiberglass is often used in products where aesthetic appeal is as important as performance. It is especially popular in automotive parts, marine applications, and consumer goods such as furniture and decorative items. The use of colored fiberglass allows manufacturers to produce custom designs without sacrificing the durability and flexibility inherent in fiberglass.

Colored fiberglass has many of the same benefits as regular fiberglass, including impact resistance, flexibility, and resilience under stress. However, the addition of color makes it especially appealing in products that need to combine both functional strength and visual appeal. It also provides a way for companies to differentiate their products in the marketplace.

The Hybrid Trend: Who Manufactures Carbon Fiber with Colored Fiberglass?

The combination of carbon fiber and colored fiberglass has gained traction in various industries, as it allows manufacturers to benefit from both materials’ strengths. Who manufactures carbon fiber with colored fiberglass has become a key question in fields where both performance and aesthetics are important. By combining the rigidity and strength of carbon fiber with the vibrant, customizable designs of colored fiberglass, these hybrid composites offer a unique solution.

Such composites are being used in high-performance automotive parts, sports equipment, and even fashion accessories, where the durability and strength of carbon fiber are needed but the visual appeal of colored fiberglass is a priority. This hybrid material provides the best of both worlds: carbon fiber offers strength and lightweight properties, while colored fiberglass introduces flexibility and an eye-catching design.

The growing trend of combining these materials is driven by manufacturers seeking innovative ways to meet both functional and aesthetic requirements. With who manufactures carbon fiber with colored fiberglass, the possibilities for creative designs are virtually limitless, resulting in products that perform exceptionally well while also standing out visually.

Can a Fiberglass Bass Boat in Saltwater Perform Well

Popular Colors and Types of Carbon Fiber Composites – Who Manufactures Carbon Fiber with Colored Fiberglass?

Blue Carbon Fiber

Blue carbon fiber has emerged as a striking variant of the traditional black carbon fiber, offering a unique aesthetic appeal that combines the premium properties of carbon fiber with a distinctive blue tint. This material is achieved through the addition of a blue pigment during the production process, often incorporated into the resin or infused into the fibers themselves. The deep, rich hue of blue carbon fiber makes it stand out in high-end products, particularly in automotive and aerospace applications.

Blue carbon fiber is not only visually appealing but also retains the excellent strength-to-weight ratio and durability that carbon fiber is known for. It is commonly used in luxury automotive parts, sports equipment like bicycles and helmets, and aerospace components where both aesthetics and high performance are important. Its combination of striking color and structural integrity makes it a popular choice for manufacturers looking to create products that are both functional and visually engaging.

Colored Carbon Fiber

Colored carbon fiber offers a wider range of options than its traditional black counterpart, providing manufacturers with the ability to produce products in nearly any shade. Colors can range from vibrant reds, blues, and greens, to more subtle shades like silver or gold. These colors are achieved using various methods, including resin infusion and external coatings, which allow the carbon fiber to retain its high-performance qualities while introducing vibrant hues.

One of the most common methods for achieving colored carbon fiber is by using tinted resins during the lamination process, which results in a color-infused composite material. This ensures that the color is integrated throughout the layers of carbon fiber, preserving the material’s strength and structural integrity.

Colored carbon fiber is widely used in consumer goods (such as mobile phone cases and furniture), sports gear, and automotive applications, where color customization is desired without compromising performance. Manufacturers also use colored carbon fiber in fashion items, including custom bags, accessories, and watches, giving high-end products a unique, customized look while still benefitting from carbon fiber’s lightweight and durable properties.

Hybrid Carbon Fiber

Hybrid carbon fiber composites combine multiple materials, such as Kevlar, colored fiberglass, and other synthetic fibers, to create a product that benefits from the advantages of each component. These composites are engineered to offer enhanced performance while providing greater aesthetic variety than traditional carbon fiber. Hybrid composites integrate the high-strength properties of carbon fiber, the flexibility of fiberglass, and the impact resistance of Kevlar, making them ideal for demanding applications.

When combined with colored fiberglass, hybrid carbon fiber composites achieve both strength and visual appeal, making them highly versatile for various industries. These materials are commonly used in automotive parts, sports equipment, protective gear, and even fashion items like custom suitcases or bags. The addition of colored fiberglass enhances the overall look, offering vibrant shades that can be customized to suit specific brand identities or consumer preferences.

Who manufactures carbon fiber with colored fiberglass has become an important question for industries seeking to create products that combine both performance and aesthetic appeal. Hybrid composites featuring carbon fiber and colored fiberglass offer a solution to the growing demand for materials that are not only strong but also visually engaging, providing manufacturers with a broader range of design possibilities. Whether for luxury vehicles, sports equipment, or high-end fashion, these hybrid materials offer the best of both worlds: superior strength and a visually striking appearance.

How to Ensure Proper Fiberglass Bass Boat Maintenance and Care

Where to Buy Carbon Fiber with Colored Fiberglass? – Who Manufactures Carbon Fiber with Colored Fiberglass?

Top Online and Offline Sources

In the automotive and racing industries, carbon fiber with colored fiberglass is increasingly popular due to its unique combination of strength, lightweight properties, and aesthetic appeal. Manufacturers and designers in the automotive sector often utilize these materials for both functional and aesthetic purposes. As the demand for high-performance and visually striking components grows, many companies, including those who manufacture carbon fiber with colored fiberglass, are offering tailored solutions. These materials are used in applications such as car body panels, interior accents, and racing components, where both performance and appearance are crucial. The versatility of carbon fiber combined with the vibrant colors of fiberglass provides an innovative approach to designing automotive parts that stand out while maintaining exceptional strength and durability.

- Manufacturers and Suppliers: Some of the most reputable suppliers of carbon fiber with colored fiberglass can be found in specialized composite material companies. These manufacturers often offer high-quality, ready-to-use materials for industries such as automotive, aerospace, sports equipment, and more. A few well-known companies specialize in advanced composite materials, producing high-performance carbon fiber composites, including colored variants. Reaching out directly to these manufacturers can provide access to the latest products and custom solutions.

- These platforms provide convenient access to different suppliers worldwide, offering a range of colors and grades for various applications. Many suppliers on these platforms allow you to order samples or small quantities, making it an excellent option for individual or small-scale buyers. It’s important to vet sellers for product quality and shipping reliability when purchasing through these channels.

- Industry Trade Shows and Expos: These events bring together manufacturers, suppliers, and buyers from the composite materials industry, offering an opportunity to meet face-to-face with who manufactures carbon fiber with colored fiberglass and other composite professionals. It’s an excellent opportunity to gather information about suppliers, view product samples, and explore customization options.

Custom Orders and Services

For projects requiring specific colors, hybrid compositions, or special cutting services, custom orders are often available from manufacturers of carbon fiber with colored fiberglass. Many suppliers offer tailored services to accommodate unique project needs. Here are some of the customization options to consider:

- Custom Color Orders: If you need a specific shade or pattern of colored fiberglass, manufacturers may offer custom coloring services, where you can choose from a wide range of pigments and finishes. Custom orders allow you to specify exactly what you need for a particular application, whether for automotive, consumer goods, or fashion.

- Hybrid Compositions: For more specialized needs, you may want to explore hybrid carbon fiber options that integrate colored fiberglass with other materials such as Kevlar or aramid fibers. Many suppliers provide bespoke services for creating hybrid composites that suit your exact performance and aesthetic requirements.

- CNC Cutting and Fiber Orientation: Custom services often include CNC cutting for precision and accuracy, which is especially important in industries like aerospace or automotive. Manufacturers can also provide specific fiber orientations, tailoring the fiber alignment in the composite to meet the strength and flexibility demands of your project.

- Pre-impregnated Carbon Fiber (Prepreg): Some suppliers also offer prepreg carbon fiber, which comes pre-impregnated with resin for easier handling and superior performance. Customization services include the ability to request specific resin types or modifications to the curing process to enhance the properties of the final product.

In addition to these services, many composite material suppliers provide technical support and consultation to help you understand how best to incorporate carbon fiber with colored fiberglass into your project. Whether you are looking for large-scale production or small custom runs, these services ensure that you get the most out of your materials.

When researching who manufactures carbon fiber with colored fiberglass, it’s important to consider your project’s unique needs, including the type of customization, volume, and specific material requirements. Through both online platforms and direct communication with manufacturers, you can find the ideal supplier who offers high-quality products and comprehensive customization options to meet your demands.

Key Features Of Fiberglass Bass Boat Molds Kits You Should Know

Applications of Carbon Fiber with Colored Fiberglass – Who Manufactures Carbon Fiber with Colored Fiberglass?

Automotive and Racing

In the automotive and racing industries, carbon fiber with colored fiberglass is increasingly popular due to its unique combination of strength, lightweight properties, and aesthetic appeal. Manufacturers and designers in the automotive sector often utilize these materials for both functional and aesthetic purposes. Companies that specialize in advanced composites, such as who manufactures carbon fiber with colored fiberglass, are meeting the growing demand for these hybrid materials. By combining the durability and strength of carbon fiber with the flexibility and vibrant colors of fiberglass, these manufacturers provide solutions that enhance both the performance and appearance of vehicles. This trend is particularly prominent in the creation of custom body panels, racing components, and interior accents, where both function and visual appeal are critical.

- Car Body Panels: One of the primary uses of carbon fiber with colored fiberglass in the automotive industry is in car body panels. The lightweight nature of these composites helps reduce the overall weight of the vehicle, improving speed and fuel efficiency. Colored fiberglass is particularly sought after for its ability to add a visually striking element to the car’s exterior, making the vehicle stand out.

- Interior Accents: Many high-performance vehicles, especially in luxury sports cars and racing cars, incorporate colored fiberglass accents in the interior. This use of carbon fiber composites allows for both durability and a high-end finish, combining functionality with an attractive, custom aesthetic.

- Racing Components: In motorsports, where both performance and weight reduction are crucial, carbon fiber with colored fiberglass is used extensively in components such as spoilers, bumpers, and side skirts. The composite materials provide the necessary impact resistance and strength while also allowing for customization with vibrant colors, adding to the visual appeal of race cars.

Aerospace

The aerospace industry also benefits from the integration of carbon fiber with colored fiberglass, as it plays a critical role in aircraft design, offering weight reduction, strength, and design versatility.

- Weight Reduction: In aircraft design, reducing the weight of the aircraft is essential to improving fuel efficiency and reducing carbon emissions. The combination of carbon fiber’s exceptional strength-to-weight ratio and the added flexibility and durability of fiberglass makes these composites ideal for components such as wing spars, tail sections, and fuselages.

- Aesthetic Considerations: Colored carbon fiber composites are also used in aesthetic components of aircraft, such as cockpit panels and interior finishes. The ability to incorporate color into the design without compromising on strength makes these materials a valuable choice in both commercial and private aviation.

- Durability in Harsh Environments: Aircraft components made with these composites also benefit from enhanced impact resistance and corrosion resistance, ensuring the safety and longevity of critical components exposed to extreme environments, including high altitudes and temperature variations.

Sports Equipment

The performance benefits of carbon fiber with colored fiberglass are widely leveraged in the sports equipment industry, where both strength and weight are critical factors.

- Bicycle Frames: One of the most common applications of hybrid carbon fiber composites is in bicycle frames, especially for competitive racing bicycles. The combination of carbon fiber and colored fiberglass results in a frame that is not only incredibly strong but also lightweight, enhancing performance without sacrificing durability. The ability to incorporate color adds an element of customization, allowing cyclists to showcase unique, personalized designs.

- Golf Clubs: In the golf industry, carbon fiber with colored fiberglass is used in the manufacturing of golf club shafts and club heads. The material’s lightweight nature improves the swing dynamics, while its strength ensures that the clubs can withstand the forces generated during play. Colored composites are also used for aesthetic purposes, making the clubs more appealing to golfers who seek visually striking designs.

- Tennis Rackets: Another example of sports equipment made from these composites is tennis rackets. High-performance rackets benefit from the strength and impact resistance of carbon fiber and colored fiberglass, offering players better control, precision, and power. The customizability of colors allows players to have a personalized touch while enjoying the advantages of durable, lightweight materials.

Consumer Products

Beyond high-performance industries, carbon fiber with colored fiberglass is also finding its way into the consumer products market, where both functionality and aesthetics are highly valued.

- Luggage: Luggage manufacturers have started to incorporate carbon fiber with colored fiberglass into suitcase and bag designs. These composites allow for lightweight yet durable products that can withstand the rough handling of airports while maintaining a stylish, modern look. The ability to offer a range of colors adds to the appeal, attracting consumers who prioritize both durability and design.

- Electronics: Another growing application for carbon fiber with colored fiberglass is in the electronics industry, where these composites are used for everything from smartphone cases to laptop covers. The material’s lightweight and protective qualities make it ideal for protecting delicate electronics, while its customizable colors and finishes contribute to a sleek, contemporary look that appeals to tech-savvy consumers.

- Fashion Accessories: Fashion designers have also embraced the use of colored fiberglass and carbon fiber in accessories such as watches, belts, and jewelry. These materials are ideal for creating high-end, durable items that also offer a visually unique appeal. The ability to blend function with aesthetics makes these composites a popular choice for upscale consumer products.

The use of carbon fiber with colored fiberglass spans a wide array of industries and applications, from automotive and aerospace to sports equipment and consumer products. The versatility, strength, and aesthetic possibilities of these hybrid composites make them ideal for high-performance applications where both durability and visual appeal are crucial. Manufacturers who specialize in carbon fiber with colored fiberglass offer a range of customization options, allowing businesses to create tailored solutions for their specific needs.

The Future of Carbon Fiber with Colored Fiberglass – Who Manufactures Carbon Fiber with Colored Fiberglass?

Trends in the Industry

The future of carbon fiber with colored fiberglass looks promising, with significant advancements expected across industries. As businesses and manufacturers strive to meet the growing demand for both performance and aesthetic appeal, hybrid composites are becoming more sought after. The ability to combine the lightweight, high-strength properties of carbon fiber with the versatile, customizable colors of fiberglass makes these materials increasingly popular.

- Enhanced Demand for Aesthetics and Performance: Many industries, such as automotive, aerospace, and sports equipment, are increasingly turning to carbon fiber with colored fiberglass to achieve a balance of strength, lightweight design, and visual appeal. In industries like luxury cars and high-end sports equipment, consumers and manufacturers are demanding materials that do more than just perform—they also need to look good. This trend is leading to more interest in hybrid materials that combine carbon fiber’s strength with fiberglass’s ability to be easily dyed in a variety of colors.

- Customization and Personalization: With consumer preference for personalized products growing, the demand for custom-colored carbon fiber composites is expected to increase. The flexibility in color options, from vibrant hues to more subdued tones, allows for greater customization of products. Who manufactures carbon fiber with colored fiberglass is adapting to this demand by offering a wide range of color combinations and bespoke solutions tailored to clients’ specific needs.

Innovations

The potential for future innovations in carbon fiber with colored fiberglass is vast, as both material properties and manufacturing techniques continue to evolve. These innovations are expected to have a significant impact on various industries, expanding the scope of applications and improving product performance.

- New Color Options: As the demand for custom-colored composites grows, manufacturers will likely introduce even more color choices for carbon fiber with colored fiberglass. Advanced techniques, such as resin infusion and electrostatic coloring, may be developed to offer a wider range of vibrant and long-lasting colors. These innovations will open up new opportunities for the material to be used in products where appearance is as important as functionality, such as in the fashion or consumer electronics sectors.

- Improved Manufacturing Techniques: Innovations in manufacturing technologies will likely make it easier and more cost-effective to produce carbon fiber with colored fiberglass. For example, automated weaving technologies and advanced resin systems could make the process faster, more consistent, and more affordable. This will lead to a wider range of industries benefiting from the material’s strength, flexibility, and aesthetic appeal.

- Broader Applications: As new color options and improved manufacturing processes emerge, the range of applications for carbon fiber with colored fiberglass will continue to expand. In particular, industries such as fashion, electronics, and consumer products will embrace these materials for their unique ability to combine strength, lightness, and colorful aesthetics. Additionally, we may see carbon fiber with colored fiberglass integrated into more high-performance products, from space exploration technologies to eco-friendly consumer goods.

The future of carbon fiber with colored fiberglass is poised for exciting growth. Who manufactures carbon fiber with colored fiberglass is at the forefront of this innovation, responding to the increasing demand for materials that balance performance with aesthetic appeal. With advancements in color technology, manufacturing processes, and application possibilities, this composite material is set to play an even more significant role across various industries in the years to come.

FAQs about Who Manufactures Carbon Fiber With Colored Fiberglass

Yes, colored carbon fiber is available, and it is becoming increasingly popular across various industries. Traditional carbon fiber is typically black due to the nature of the material itself, but colored carbon fiber can be achieved through several methods. The most common method involves infusing resins or pigments into the carbon fiber during the manufacturing process. This allows for a range of colors, from vibrant hues to metallic finishes, while still retaining the inherent strength and lightweight properties of the material.

Colored carbon fiber is used in industries where aesthetics are just as important as performance. For example, in automotive design, luxury goods, and sports equipment, manufacturers may opt for colored carbon fiber to give their products a unique appearance. The color is usually added during the resin infusion process, where a variety of tints can be introduced without compromising the structural integrity of the carbon fiber.

Overall, the ability to create colored carbon fiber has opened up new possibilities for product design and customization. Manufacturers are increasingly incorporating colored carbon fiber into their offerings to meet both functional and aesthetic demands. This versatility is particularly valuable in industries where appearance plays a significant role in product appeal, such as in fashion, consumer electronics, and high-performance sports equipment.

Yes, fiberglass and carbon fiber can be mixed to create hybrid composites, and this combination offers a range of benefits. These hybrid materials combine the strengths of both fibers—carbon fiber‘s high strength-to-weight ratio and fiberglass‘s flexibility and impact resistance. The resulting composite material is often lighter and more durable than fiberglass alone, while also more cost-effective compared to pure carbon fiber composites.

The mix of fiberglass and carbon fiber can be achieved in a variety of ways, such as layering or weaving the fibers together, or by using a resin system that integrates both materials. One of the key advantages of combining these two fibers is that it allows manufacturers to take advantage of the best qualities of both materials without the high costs associated with using carbon fiber exclusively.

In industries such as automotive, aerospace, and sports equipment manufacturing, the combination of carbon fiber and fiberglass is common. It allows for enhanced performance while keeping production costs manageable. For example, a carbon-fiberglass hybrid might be used in a race car body to reduce weight and increase rigidity, but the fiberglass layer will improve impact resistance and reduce the cost.

The best carbon fiber manufacturers are typically those that specialize in high-performance, advanced composite materials. Leading companies in the industry include Toray Industries, Hexcel, and SGL Carbon. These companies are recognized for producing high-quality carbon fiber used in a wide range of applications, from aerospace and automotive to sports equipment and consumer goods.

Toray Industries is one of the largest and most well-known manufacturers of carbon fiber in the world. They produce high-strength carbon fiber used in the aerospace, automotive, and industrial sectors, with a reputation for producing lightweight, durable, and reliable materials.

Hexcel specializes in advanced composite materials, including carbon fiber. They are particularly prominent in aerospace and defense industries, where the need for lightweight, high-strength materials is critical.

SGL Carbon is another leading producer, known for its high-quality carbon fiber and its ability to provide tailored solutions for various industries, including automotive, energy, and sports.

While the “best” carbon fiber manufacturer depends on the specific application and requirements, these companies are consistently at the forefront of the industry, offering superior performance and innovation. Whether for aerospace, sports equipment, or automotive applications, these manufacturers are trusted for providing high-performance carbon fiber that meets rigorous standards.

Several companies specialize in the manufacturing of carbon fiber, with some of the most prominent being Toray Industries, Hexcel, SGL Carbon, and Mitsubishi Chemical. These companies produce carbon fiber for various industries, including aerospace, automotive, sports, construction, and consumer goods.

Toray Industries: Based in Japan, Toray is one of the largest carbon fiber manufacturers globally, providing high-performance carbon fiber for industries like aerospace and automotive.

Hexcel: Known for its advanced composite materials, Hexcel manufactures carbon fiber that is used in applications ranging from aerospace to industrial sectors. Their products are highly regarded for their reliability and performance in critical industries.

SGL Carbon: SGL is another major player in the carbon fiber manufacturing industry, offering a wide range of products for automotive, energy, and industrial applications. Their products are known for their versatility and superior material properties.

Mitsubishi Chemical: Mitsubishi is a key manufacturer of carbon fiber for automotive and aerospace applications. Their carbon fiber is often used in industries that demand lightweight and strong materials.

These companies are leaders in the carbon fiber manufacturing industry, producing high-quality materials used in various sectors, from aerospace to sports equipment. As industries continue to demand lighter, stronger materials, these manufacturers are well-equipped to meet these needs with advanced carbon fiber products.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.