Fibreglass insulation tapes is a versatile material widely used for its exceptional heat-resistant and insulating properties. It plays a crucial role in various industries, offering reliable protection against heat loss, moisture damage, and environmental wear. Proper insulation is essential for maintaining energy efficiency, preventing costly repairs, and enhancing the durability of equipment and structures. Fibreglass insulation tape is commonly employed in sectors such as automotive, construction, and industrial applications. In the automotive industry, it helps protect engine components from extreme temperatures, while in construction, it provides thermal insulation for pipes and ducts. Its high-temperature resistance and moisture barriers make it an indispensable tool in ensuring long-lasting performance across different environments.

What is Fibreglass Insulation Tape?

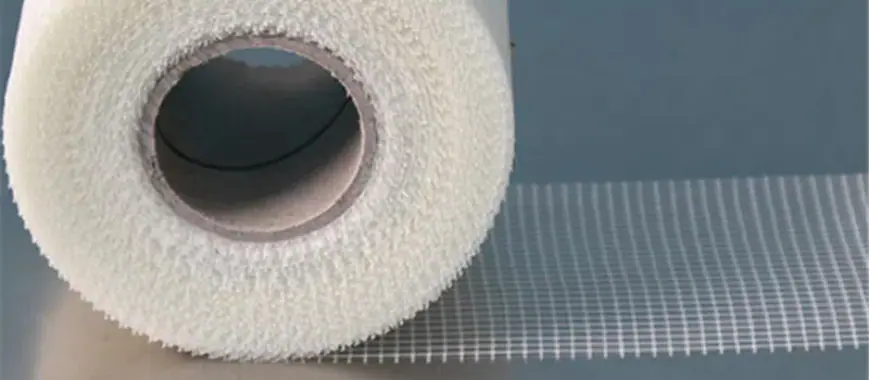

Fibreglass insulation tapes is a high-performance woven textile designed to provide excellent heat resistance and insulation. This tape is made from a combination of fine glass fibers that are woven together to form a strong, durable material. Due to its unique composition, fiberglass insulation repair tape is capable of withstanding extreme temperatures, making it a critical component in a variety of applications where heat and moisture protection are essential.

Key Features of Fiberglass Insulation Tape

Fibreglass insulation tapes is known for several key features that make it a popular choice in many industries:

- Strength and Durability: The glass fibers used in the tape provide high tensile strength, ensuring that it remains intact even under challenging conditions. This durability makes fibreglass insulation tapes a reliable solution for long-term insulation needs.

- Heat Resistance: One of the most significant properties of fibreglass insulation tapes is its ability to resist high temperatures. It can typically withstand temperatures ranging from -100°F to over 1000°F (-73°C to 540°C), depending on the specific type of tape. This makes it ideal for use in automotive engines, industrial machinery, and other high-heat environments.

- Moisture and Corrosion Resistance: In addition to heat resistance, fibreglass insulation tapes is resistant to moisture, preventing rust and corrosion in metal components when used in damp or wet conditions.

Materials Used in Manufacturing Fiberglass Insulation Tape

The primary material used in the production of fibreglass insulation tape is fiberglass yarn, which is made by drawing glass fibers into fine strands. These strands are then woven into a cloth-like structure, providing the tape with both flexibility and strength. The glass fibers are often coated with a protective resin or adhesive to enhance the tape’s ability to resist wear and tear while maintaining its insulating properties.

Additional materials such as silicone, acrylic, or polyurethane coatings may be applied to the fibreglass yarn to further enhance its thermal stability, improve adhesion, or provide additional water-resistant properties. This makes fibreglass insulation tapes suitable for various harsh environments, from automotive engines to industrial machinery and beyond.

How to Choose the Best Fiberglass Bandage for Recovery

Types of Fibreglass Insulation Tape

Fibreglass insulation tapes is a versatile material that comes in different types, each designed to meet specific requirements. These variations cater to distinct applications, ensuring optimal performance in various environments. Below, we explore the key types of fibreglass insulation tape, including its use in pipe insulation, seam sealing, and high-temperature applications.

Fibreglass Pipe Insulation Tape

Fibreglass pipe insulation tape is specially designed to insulate pipes, helping to maintain temperature control while preventing heat loss or gain. This type of fibreglass insulation tapes is often used in HVAC systems, plumbing, and industrial pipelines to ensure that the internal temperatures of the pipes remain consistent.

The tape’s primary function is to create a protective barrier that helps retain the temperature of hot or cold liquids within the pipes, minimizing energy costs and improving efficiency. Additionally, it helps to prevent condensation from forming on cold pipes, which can lead to moisture damage, mold growth, and corrosion over time. Fibreglass pipe insulation tape is commonly used in both residential and commercial applications where consistent temperature control is essential.

This type of tape is typically made with a dense layer of fibreglass cloth, coated with a heat-resistant adhesive to bond securely to the pipe surface. The tape’s flexibility ensures easy application on both straight and curved pipe surfaces, making it a practical and effective solution for a variety of piping systems.

Fibreglass Insulation Seam Tape

Fibreglass insulation seam tape is used primarily to seal seams and joints in insulation materials, ensuring thermal efficiency and moisture resistance. When installing fibreglass or other insulation materials in buildings or industrial settings, it’s essential to seal the seams to prevent gaps, air leakage, and moisture infiltration. Fibreglass insulation seam tape is an ideal product for this task due to its excellent adhesion properties and ability to withstand the same high temperatures as the insulation materials.

This type of tape is often used to seal the edges of fibreglass batt or blanket insulation, as well as ductwork or other insulation systems in HVAC systems. By applying fibreglass insulation seam tape, you can create a continuous, secure barrier that enhances the insulation’s overall performance and prevents heat loss. The tape also helps to improve indoor air quality by reducing the potential for mold and mildew growth due to moisture infiltration.

Fibreglass insulation seam tape is typically engineered with a strong fibreglass cloth base and a high-temperature adhesive to ensure a durable, long-lasting seal. It is often used in both residential and industrial applications, including the sealing of ducts, pipes, and thermal insulation seams in various environments.

High-Temperature Fibreglass Tape

High-temperature fibreglass tape is specifically designed to withstand extreme temperatures, making it ideal for industrial applications where high heat is present. This type of fibreglass insulation tapes is commonly used in environments like automotive engines, industrial machinery, and exhaust systems, where temperatures can easily exceed 1000°F (540°C).

High-temperature fibreglass tape provides outstanding thermal protection by preventing heat loss and maintaining stable operating temperatures. It can also protect against extreme thermal shock, offering a high degree of durability and resistance to damage caused by continuous heat exposure. This makes it a reliable choice for sealing exhaust systems, protecting cables, and insulating hot surfaces.

Manufactured with a special combination of heat-resistant coatings and fibreglass yarn, this tape offers superior flexibility, allowing it to be applied in tight spaces or wrapped around irregularly shaped objects. High-temperature fibreglass tape is also moisture and corrosion resistant, which enhances its ability to perform under harsh conditions. It’s frequently used in industries such as automotive, aerospace, power generation, and petrochemical applications.

Each type of fibreglass insulation tapes serves a distinct purpose, but all share the core benefits of excellent heat resistance, durability, and efficiency. By choosing the right type of fibreglass insulation tape for a specific application, you can ensure that your insulation systems perform optimally while maintaining safety and reducing energy consumption.

Choosing the Right Fiberglass Whip Rod for Every Need

Applications of Fibreglass Insulation Tape

Fibreglass insulation tapes is used in a wide range of industries, thanks to its impressive heat resistance, durability, and versatility. Whether in automotive applications, construction, or industrial settings, fibreglass insulation tape provides reliable performance. Below, we explore some of the most common applications of fibreglass insulation tapes, including its use in automotive systems and waterproof applications.

Fibreglass Tape for Cars

Fibreglass tape is a crucial component in automotive applications, especially in managing heat within the engine and exhaust systems. In cars, high temperatures are constantly generated by engine components, exhaust manifolds, and catalytic converters. Fibreglass insulation tapes is used to protect sensitive parts, prevent heat loss, and improve the efficiency of heat management systems.

In automotive exhaust systems, fibreglass tape helps insulate the exhaust pipes and catalytic converters, reducing the heat that escapes into the engine bay. This enhances the overall performance of the engine and prevents excessive heat from damaging surrounding components. The tape is also used to wrap hoses, wires, and cables to protect them from heat and abrasion. By providing a barrier between high-heat surfaces and other materials, fibreglass insulation tapes helps extend the lifespan of critical car parts, improving vehicle reliability and safety.

Additionally, fibreglass tape is used in the construction of heat shields for specific automotive components. These heat shields are designed to protect sensitive parts, such as wiring and fuel lines, from excessive heat. Fibreglass insulation tapes is an ideal material for these applications due to its flexibility, durability, and high-temperature resistance.

Fibreglass Tape Waterproof

Fibreglass insulation tapes is not only heat-resistant but also waterproof, making it an excellent choice for applications in high-humidity or water-prone environments. The waterproof properties of fibreglass tape prevent moisture from compromising insulation systems or causing damage to electrical components.

This type of fibreglass insulation tapes is particularly beneficial in industries where moisture can lead to corrosion, short circuits, or degradation of materials. For instance, it is commonly used in marine environments, where equipment is exposed to water and salt, as well as in plumbing and HVAC systems. By applying fibreglass tape to pipes, ducts, and other vulnerable areas, you can create a moisture-resistant seal that prevents the growth of mold and mildew while ensuring that the insulation maintains its thermal efficiency.

The waterproof properties of fibreglass insulation tapes also make it ideal for use in electrical applications. In wet or damp conditions, where traditional insulating materials may degrade or fail, fibreglass tape maintains its integrity, providing a reliable moisture barrier that protects wires, cables, and other electrical components from water damage.

Advantages of Fibreglass Insulation Tape

Fibreglass insulation tapes offers several significant advantages, making it a preferred choice across various industries. Here are some key benefits:

- Heat Resistance: Fibreglass insulation tapes can withstand extremely high temperatures, typically up to 1000°F (540°C), making it perfect for use in high-heat applications such as exhaust systems, industrial machinery, and automotive engines.

- Moisture Resistance: The tape’s waterproof properties prevent moisture from seeping into insulation materials, reducing the risk of mold, mildew, and corrosion. This is particularly useful in marine, HVAC, and plumbing applications.

- Durability: Fibreglass insulation tapes is highly durable and resistant to wear and tear, ensuring long-term protection even under harsh environmental conditions. It can withstand physical stress, abrasion, and continuous exposure to heat.

- Flexibility: The tape is highly flexible, allowing it to be easily wrapped around pipes, cables, or irregularly shaped surfaces. This flexibility ensures a secure fit and effective coverage in a variety of applications.

- Energy Efficiency: By minimizing heat loss and improving insulation performance, fibreglass insulation tapes helps improve energy efficiency in systems such as heating, ventilation, and air conditioning (HVAC), as well as automotive engines.

- Electrical Insulation: Fibreglass insulation tapes provides excellent electrical insulation, preventing short circuits and ensuring safe operation in electrical systems exposed to moisture or high temperatures.

Fibreglass insulation tape’s combination of heat resistance, moisture protection, and durability makes it a valuable tool in a wide range of applications, including those in the automotive, industrial, and construction sectors.

Fiberglass Line Pipes for Oil and Gas Applications

Advantages of Using Fibreglass Insulation Tape

Fibreglass insulation tapes offers a wide range of advantages, making it a highly effective and reliable solution for various insulation and heat protection applications. From durability and flexibility to cost-effectiveness and energy efficiency, the benefits of using fibreglass insulation tape are significant across multiple industries. Below, we explore these advantages in detail.

Durability: Long-lasting Protection Against Heat and Moisture

One of the primary advantages of fibreglass insulation tapes is its exceptional durability. This type of tape is designed to withstand harsh conditions, offering long-lasting protection against both heat and moisture. The fibreglass material is inherently strong and resistant to wear and tear, even in environments exposed to extreme temperatures and humidity.

Fibreglass insulation tapes can endure continuous exposure to high heat without losing its insulating properties. In addition, it is resistant to moisture, preventing the growth of mold and mildew and protecting underlying materials from rust and corrosion. This durability ensures that fibreglass insulation tapes provides reliable protection for extended periods, reducing the need for frequent replacements or repairs.

Flexibility: Easy to Apply in Different Environments

Fibreglass insulation tapes is highly flexible, making it suitable for a variety of applications, whether you’re sealing seams, insulating pipes, or protecting electrical components. Its flexibility allows the tape to conform to irregular surfaces, including bends, curves, and joints, ensuring a secure and effective seal.

In construction and industrial settings, fibreglass insulation tapes can be wrapped around pipes, ducts, and cables with ease, even in tight or hard-to-reach areas. This flexibility also makes it ideal for automotive applications, where components of varying shapes and sizes need to be insulated or protected from heat. Additionally, fibreglass insulation tapes is easy to handle and apply, reducing installation time and effort.

Cost-Effectiveness: Affordable Solution for Various Insulation Needs

Another major benefit of fibreglass insulation tape is its cost-effectiveness. Compared to other insulation materials, fibreglass insulation tape offers an affordable solution for both residential and industrial insulation needs. It provides reliable thermal protection and moisture resistance at a relatively low cost, making it an attractive option for large-scale projects where budget considerations are important.

The long-lasting nature of fibreglass insulation tape further enhances its cost-effectiveness. Its durability reduces the frequency of replacements, minimizing maintenance costs in the long term. This makes it an ideal choice for applications where both performance and affordability are essential.

Energy Efficiency: Contributes to Reducing Energy Consumption

Fibreglass insulation tape plays a key role in improving energy efficiency by providing better thermal control. By reducing heat loss or gain, fibreglass insulation tape helps maintain stable temperatures in HVAC systems, piping, and machinery, leading to lower energy consumption. This results in cost savings for both residential and commercial applications, where heating and cooling costs can be significant.

For instance, when used to insulate pipes or HVAC ducts, fibreglass insulation tape prevents heat from escaping or entering the system, ensuring that energy is used more effectively. In industrial settings, it helps maintain consistent operating temperatures in machinery, reducing the need for additional energy input to counteract heat loss. The energy-efficient properties of fibreglass insulation tape not only reduce operational costs but also contribute to environmental sustainability by minimizing energy waste.

Summary of Advantages

- Durability: Fibreglass insulation tape offers long-lasting protection against heat, moisture, and wear, making it a reliable choice for various applications.

- Flexibility: Its ability to conform to irregular surfaces makes it ideal for wrapping pipes, sealing seams, and insulating components in challenging environments.

- Cost-Effectiveness: Providing excellent performance at an affordable price, fibreglass insulation tape is an economical solution for both residential and industrial insulation needs.

- Energy Efficiency: By improving thermal control, fibreglass insulation tape helps reduce energy consumption, contributing to lower heating and cooling costs.

Fibreglass insulation tape stands out as an essential tool in the insulation industry. Its combination of durability, flexibility, cost-effectiveness, and energy efficiency makes it a preferred choice for various applications across automotive, industrial, and construction sectors.

How to Use Fibreglass Insulation Tape

Using fibreglass insulation tape is a straightforward process that requires careful preparation and attention to detail. Whether you’re sealing seams in insulation materials, wrapping pipes, or insulating automotive components, fibreglass insulation tape can be easily applied to achieve optimal performance. Below is a detailed, step-by-step guide to help you effectively use fibreglass insulation tape in different applications, along with the tools and safety precautions necessary for handling it.

Step-by-Step Guide to Applying Fibreglass Insulation Tape

Prepare the Surface

Before applying fibreglass insulation tape, ensure that the surface is clean, dry, and free from dirt, oil, or any other debris. For better adhesion, it is essential that the surface is smooth and free of imperfections that might prevent the tape from bonding effectively.

- For Pipes: Wipe down the pipes to remove moisture or grease that might affect the tape’s adhesion.

- For Seams in Insulation: Ensure the insulation material is positioned correctly, with no gaps or overlapping seams.

Cut the Tape to the Required Length

Measure the area that needs to be covered with fibreglass insulation tape. Use a ruler or measuring tape to ensure accurate coverage. Once you’ve measured the length, cut the fibreglass tape with a sharp pair of scissors or a utility knife. It’s important to cut the tape straight to ensure an even application.

Apply the Tape

- For Sealing Seams: Begin by applying the fibreglass insulation tape directly along the seam of the insulation material. Press the tape firmly to ensure a secure seal. Stretch the tape slightly while applying it to avoid wrinkles or air bubbles that could reduce its effectiveness.

- For Wrapping Pipes: Starting at one end of the pipe, wrap the fibreglass tape tightly around it. Overlap the edges slightly as you move along the length of the pipe to ensure complete coverage. Continue wrapping until the entire pipe is covered.

- For Automotive Insulation: When using fibreglass insulation tape in automotive applications, such as wrapping exhaust systems or insulating engine components, ensure that the tape is applied evenly and tightly around the components. Pay special attention to areas exposed to high temperatures, ensuring the tape is securely fastened without any gaps.

Press and Smooth the Tape

After applying the tape, press it down firmly to ensure a strong bond with the surface. Use your fingers to smooth out any bubbles or wrinkles, ensuring that the tape is flush with the surface. For tight corners or difficult-to-reach areas, use a small roller or another flat tool to help the tape adhere smoothly and evenly.

Inspect the Application

Once the fibreglass insulation tape is applied, inspect the area to ensure that the tape is securely in place and covers the entire desired area. Make sure there are no loose edges, air pockets, or gaps that could reduce the tape’s performance. If necessary, apply additional tape to reinforce weak areas or to complete coverage.

Tools and Safety Precautions for Handling Fibreglass Insulation Tape

While fibreglass insulation tape is relatively easy to use, it’s essential to follow proper handling techniques and use the right tools to ensure safe and effective application.

Tools Needed

- Measuring Tape: To measure the length of the area where the tape will be applied.

- Utility Knife or Scissors: To cut the fibreglass tape to the required length.

- Clean Cloth: For cleaning the surface before applying the tape.

- Rubber Gloves: For protection against irritation caused by handling fibreglass materials.

- Roller or Flat Tool: To help press the tape down evenly in difficult-to-reach areas.

Safety Precautions

- Wear Protective Gloves: Fibreglass insulation tape is made from fine glass fibers that can irritate the skin. It is recommended to wear rubber gloves or protective handwear to avoid direct contact with the tape during application.

- Wear Eye Protection: If you’re cutting fibreglass tape or working with it in an area where particles may become airborne, wear safety goggles to protect your eyes from irritation.

- Work in a Well-Ventilated Area: Although fibreglass insulation tape does not emit harmful fumes, it’s always best to work in a well-ventilated space to avoid inhaling any dust or particles.

- Avoid Direct Contact with Skin: If you accidentally come into contact with the fibreglass tape, wash the affected area immediately with soap and water to prevent irritation. In case of more severe reactions, seek medical advice.

Final Thoughts

Using fibreglass insulation tape is an efficient and effective way to insulate, seal seams, and protect components in various applications. Whether you are wrapping pipes, sealing seams in insulation materials, or insulating automotive systems, following these step-by-step instructions will ensure the tape performs at its best. Always take the necessary precautions when handling fibreglass insulation tape to avoid skin irritation or other discomforts. By using the right tools and following proper safety guidelines, you can maximize the benefits of this durable and versatile insulation material.

FAQs about Fibreglass Insulation Tape

For fiberglass insulation, the ideal tape to use is fibreglass insulation tape, which is specifically designed to handle the high temperatures and moisture resistance required in insulation applications. This tape is typically made from woven fibreglass material that is coated with a heat-resistant adhesive. Fibreglass insulation tape provides an effective barrier to prevent heat loss, protect surfaces from moisture, and secure insulation materials. It is commonly used for sealing seams, insulating pipes, or wrapping components exposed to high temperatures. You can also find specialized versions, such as fibreglass pipe insulation tape, for specific applications in plumbing or HVAC systems. These tapes are engineered to endure harsh environments and ensure that your insulation system functions efficiently over the long term.

Yes, fibreglass insulation tape is an excellent insulator due to its unique combination of materials. The tape is made from fibreglass yarns that are woven tightly together, making it both durable and heat-resistant. Its primary function is to provide a thermal barrier, preventing heat loss or gain, depending on the application. This makes fibreglass tape highly effective in systems where temperature control is crucial. The high-temperature resistance of fibreglass tape ensures that it can perform in environments where other types of insulation may degrade or fail. It is especially useful in automotive applications, exhaust systems, HVAC ducts, and plumbing pipes. Fibreglass insulation tape can withstand extreme heat (up to 1000°F or 540°C in some cases) while providing long-lasting insulation, making it an excellent choice for both residential and industrial use.

Yes, it is highly recommended to tape fiberglass insulation seams to ensure maximum efficiency and effectiveness. Fibreglass insulation seam tape is specifically designed for this purpose. When you install fibreglass batt or blanket insulation in walls, attics, or ducts, sealing the seams with fibreglass insulation tape prevents gaps that could allow air, moisture, and heat to escape or enter. Taping the seams not only improves thermal efficiency by enhancing the insulation’s ability to retain or block heat but also helps prevent moisture infiltration, which can lead to mold growth or corrosion. Proper seam sealing is especially important in HVAC systems or any area where insulation material is exposed to humid or fluctuating temperatures. Using fibreglass insulation seam tape ensures that your insulation maintains its full performance and reduces the likelihood of needing costly repairs or replacements due to gaps and leaks.

Fibreglass insulation tape is a versatile material with a wide range of uses, primarily for heat and moisture resistance. It is most commonly used in applications where temperature control and insulation are critical, such as in automotive systems, industrial machinery, and construction. Some of the key uses for fibreglass tape include:

Sealing insulation seams: To ensure that thermal and moisture barriers are continuous and effective, fibreglass insulation tape is used to seal seams in insulation materials, including batt and blanket insulation.

Wrapping pipes and ducts: Fibreglass insulation tape is often wrapped around pipes or HVAC ducts to maintain the desired temperature, preventing heat loss or gain.

Automotive insulation: It is used to insulate exhaust systems, engine components, and heat shields, protecting sensitive parts from extreme temperatures.

Electrical insulation: Fibreglass tape is also used for insulating electrical components, preventing short circuits, and protecting wires and cables in high-heat environments.

Overall, fibreglass tape provides a reliable solution for insulation, protection, and durability in various industries, offering long-lasting performance even in the harshest conditions.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.